compression test cracked block|cracked engine block testing : OEM Visual Inspection. The first step in diagnosing a cracked engine block is to perform a visual inspection. Look for any visible cracks or signs of damage on the engine . Resultado da Question Answering & Homework Helper. Go with QuestionAI App, AI Powered Question Answering helper & Summarizer, instantly resolve all kinds of problems, summarize all kinds of texts and help to answer your questions with concise solution. Choice of more than 10 million users.

{plog:ftitle_list}

webdicas de segurança. Mostrar mais. ! Bancos, bancos - endereço: Av Rio Branco, 39 - Centro - Rio de Janeiro, Rio de Janeiro - telefone: 📞 +55 (21) 220329.

Mechanics will look for signs of coolant or oil leakage around the engine block. 2. Pressure Test: A cooling system pressure test can help identify leaks in the engine block. If . Visual Inspection. The first step in diagnosing a cracked engine block is to perform a visual inspection. Look for any visible cracks or signs of damage on the engine .

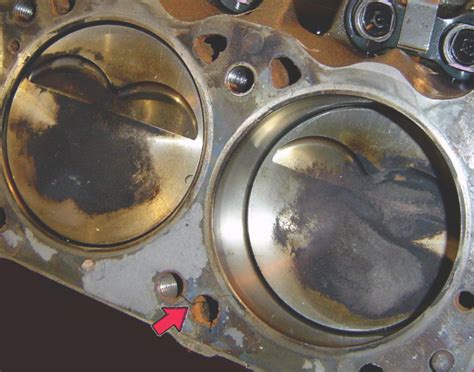

There are several signs that may indicate a cracked engine block, including coolant leaks, overheating, poor performance, oil and coolant mixing, and excessive bubbles in the coolant. If you suspect a cracked . A cracked block or head gasket failure can total an engine. Use this easy test to rule out a severe engine problem! A block tester—a device that contains fluid that changes color in the presence of combustion gases—can be used to detect a block that’s cracked internally. The tester is placed over the cooling system filler neck to check for . Conducting a compression test on each cylinder is a valuable diagnostic tool for identifying both a blown head gasket and a cracked block. Significant variation in compression .

visible cracks on engine block

Jul 19, 2016

hach titralab kf1000 series volumetric karl fischer titrator 3 980 store

Unfortunately, the worst result that can be shown with a compression test is a cracked engine block. If the engine block has cracked and the air is escaping through a fracture or hole in the engine, very little . The block tester is a device that contains fluid that changes color if there are combustion gases present. It is used to detect an internally cracked engine block. If combustion gases are present, the engine suffers from a .

Perform a Compression Test: Low compression in one or more cylinders can point to a blown head gasket. Visual Inspection: Look for visible cracks in the engine block or head. Pressure Test: A pressure test of the . Compression tests only test for compression, NOT block cracks/leaks. If you want to try to seal the cracks by any method, after your "fix" you'll need to pressure test the block to about 10-15 psi or so. This is done by closing all cooling system connections, isolating the exhaust manifold (I.E. disconnect it from the cooling system) . 7. Cylinder Compression Test. A head gasket can fail between cylinders causing two consistent cylinder misfires and low compression in each misfiring cylinder. To check for this condition remove all of the spark plugs .

It may abate as the car warms up, the metal expands, and the crack swells shut. I only discovered the cracked head on a 1974 BMW 2002tii I had when I was readying the car for sale and did a compression test. The no. 3 cylinder showed slightly low compression, 120 psi as compared with 160 for the other cylinders. When it’s under the car, the smoke coming out that looks dark grey to black may be coming from a cracked block. The smoke is the unpleasant fumes from engine performance issues that you might want to have looked into by an experienced mechanic. 5. Perform A Compression Test. If your car engine has a crack, it will lack power. Cracked blocks from freezing dont happen much in my area, so youre going to need other people to chime in and give you better advice. . Run a compression test on all the cylinders and see what you get. That's usually a good place to . I was wondering and hoping, that the experts and all others could chime in on what is the best (most accurate) method to check the cylinder compression and cylinder leak down ratings for a 911 SC 3.0L long block. Presume it has been stored indoors and not used/tested for 6+ months per seller.

So, cracked engine block is still an option. but, since it's not showing in the compression test, the crack must be in the lower part of the block. The same forum suggests I should do a leak down test. If it does not show a head gasket problem, that confirms the lower block crack theory. Discover the Signs of a Blown Head Gasket or Cracked Head: Overheating, Smoke, Misfires, and More. Prevent Costly Repairs! . This unassuming component forms an airtight seal between the engine block and cylinder head to prevent coolant and oil from mixing. . Decreased Compression: A compression test can reveal lowered compression levels in . From head gasket failures to a cracked engine block, many culprits of a failing engine can be hidden and hard to detect without tearing an engine apart. . Unfortunately, the worst result that can be shown with a compression test is a cracked engine block. If the engine block has cracked and the air is escaping through a fracture or hole in .

Any one out there experienced with a blown head gasket or cracked block. How do you tell if you have a cracked block or blown head gasket? Is there a (800) 853-2651. Shop Now: TRACTOR PARTS. Allis Chalmers; Case & David Brown . Kent- Compression test is a similar operaton, but gives completely different information. The leak test is strictly .*Did our video help you? If so, consider buying us a beer: https://bit.ly/3feE6tJ*In this video, we show you how to use an Engine Block Tester to determine .

Compression test is more to test if there is a problem. If your compression is low, it could be a number of different issues. You can test the rings by adding oil to the cylinder and see if the compression is higher. Other than rings it can be difficult to determine the source of the issue. A leakdown test will tell you where the problem is. Compression Test Results. The compression test is an essential diagnostic tool for evaluating the severity of a cracked cylinder head. It measures the engine’s compression to determine if there is a problem with the cylinder head. If the compression test results indicate low compression, it could be a sign of a cracked cylinder head. Leak . Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 . However, this guide will focus mainly on cracks in the block that don’t directly affect cylinder compression. Signs Of A Cracked Engine Block. As mentioned, overheating is almost always what causes cracked engine .

Cylinder leak down tester,compression test kit -Engine Cylinder Dual Gauge Leakdown Tester kit Diagnostics Tool ; . cylinder head cracks, worn valves and blown head gaskets. It checks the amount of . A compression test diagnoses many engine problems. If a compression test is below the manufacturer's specifications, there's an internal engine issue. How It Works. . Cracked components: If you have a crack in the block or in the cylinder head, then this will cause low compression. Any part that is cracked will need to be replaced.

Engine Compression Test. After addressing the blown head gasket, it’s crucial to perform an engine compression test to ensure the issue is fully resolved and the engine is functioning correctly. To conduct the test: . One of the most telling signs of a cracked block is decreased compression. Compression is the pressure exerted by the engine . How To Test Your Head Gasket. The two most straightforward ways to test your head gasket are to check your oil, and check your exhaust. But while those might be the easiest ways, they aren’t the only things you can check for confirmation. Below, I’ll highlight the seven most effective ways to test if you have a blown head gasket: 1. A compression test is a type of mechanical testing that measures a material’s behavior under applied forces, usually conducted by applying pressure on a test specimen using platens or fixtures. Compression strength tests measure a material’s behavior under applied forces to determine its maximum stress capacity. Cracked engine block or cracked head? Did it ever overheat? If the first mechanic used the wrong plugs, there is the possibility they were over-torqued and caused substantial engine damage. . A compression test is simply removing the spark plug, turning off the fuel pump, installing a pressure gauge into the spark plug position, and cranking .

From the uniaxial compression test of 20 groups of rock samples, four typical failure modes were selected. . To assess the comparative influence of these two block assembly techniques on crack . How to Test a Cracked Cylinder Head. If you aren’t a professional mechanic, you want to know how you can troubleshoot a cracked cylinder head from home. Sadly, this isn’t something simple, such as checking for a fouled spark plug. Without the right mechanical equipment and advanced skills, you aren’t going to be able to tell what’s .

A compression test is simple to learn and only requires a few basic tools. From a mechanical perspective, you will need to know how to properly remove the spark plugs on the vehicle or equipment you are testing and properly disable the ignition system and fuel system, the latter if the vehicle is fuel injected. For carbureted engines, you can choose to disable the fuel supply . You could do a compression test and if compression is relatively normal this could indicate chances of a crack rather than it being head gasket, but again not always, it's rarely possible to differentiate between the 2 but usually it'll be head gasket and if severe enough could create cracks anyway due to over heatingNote down the load at which masonry unit fails and the maximum load divided by gross sectional area of unit will give the compressive strength of block. Similarly, test the remaining 7 blocks and the average of 8 blocks strength is the final compressive strength of concrete masonry unit.

webContato Interior do Ceará Soluções; Aréas metropolitanas: 4002.2552 Capitais: (85) 3462.9000 Geral: 0800 020 9000 Exclusivo: (88) 3102.3400. Acesse o site e conheça nossas Soluções: CLIQUE AQUICLIQUE AQUI

compression test cracked block|cracked engine block testing